Unusual Rigging and Engineering was brought on board by ALEC and subcontractors ASU and Holovis to handle the various rigging installations around Seaworld at Yas Island.

Being the region’s first marine life theme park, it was crucial to ensure that the equipment and design solution remained constant throughout the different disciplines and buildings.

One of the main aspects of the project was the installation of a series of acrylic ceiling panels in the venue’s central hub. Called One Ocean, the hub looks like an underwater cave with rocky arches marking the entrances to the park’s other seven realms.

Richard Hoare, Project Manager at URE, commented: “ALEC’s challenge was, how does one get a series of fragile, diminishing acrylic ceiling panels up 25m to a pre-installed curved, angled, convoluting MDF ceiling decoration, the underside of which was covered in programmable LED strip lighting, when each panel was bespoke in length, width and angle? It was a task the acrylic supply and installation contractor had declined to undertake. We have a good working relationship with ALEC so they asked us to rise to the challenge.”

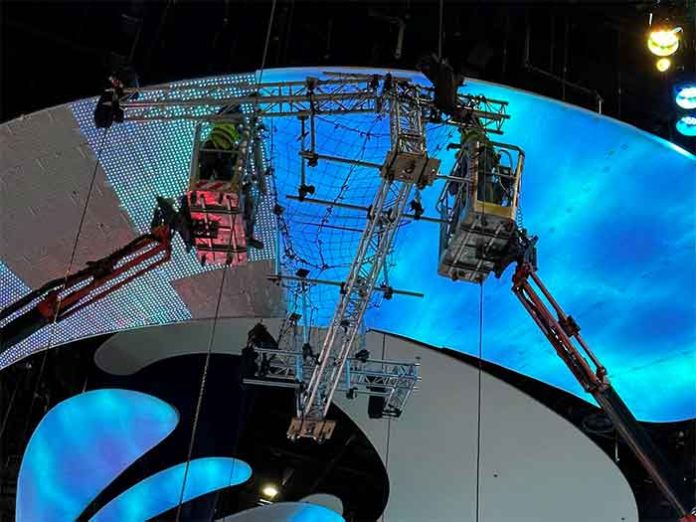

The URE team’s solution was to design and fabricate a bed to coax the panels, some as large as 5m by 2m albeit only 80kg in weight, into their designated position. This was done by creating a H30v Truss cradle, modified for each individual panel, with a series of inverted, rubber base protected screw jacks and cargo nets supporting each panel.

Hoare continued: “We used four Liftket Hoists to lift the cradle to be within proximity to the ceiling decor. Via two-way radio communication, between roof riggers and observers in spider lifts, the cradle was angled using the four hoists to simulate that of the decor and finally bumped up to a distance where the screw jacks could be utilised to gently ease the panel up to its final seated position.”

Once the panel was fitted into place, the cradle was lowered to floor level, the next set of four roof points were installed, and the cradle adjusted in relation to the points and size of the next panel.

URE’s work for ASU and Holovis was broken down into two scopes. For ASU the Unusual team designed, installed, and commissioned six custom curved trusses in the dolphin show area for lighting, one truss in Sea Line for the tank lighting, three trusses in the Coral tank, secondary steel stools to support cable reelers and 38 500kg-rated rigging points in the multipurpose events space.

Four flown arrays for the dolphin show, six flown arrays for the sea lion show and 10 flown arrays for the One Ocean hub were designed, installed and commissioned for Holovis.

Hoare explained: “With any new build project, the biggest challenge is designing within a virtual model and keeping up to date with the changes as the build develops on site. With the team’s experience using Navisworks, we are able to work alongside our clients to capture any clashes and design solutions before they become problems on site.”

Corrosive ratings were required for all the materials and products. For nearly all areas, the URE team had to achieve a C4 rating which meant they had to work closely with their suppliers to make sure that all components were compliant.

In total, this required the truss to be powder coated to a specific thickness and number of coats with all the ends of the truss and weld holes being closed. The hoist meanwhile had to be painted with a specific finish and all the loose rigging components had to be stainless steel GR 316.

Hoare concluded: “This was a fantastic project to be a part of. Commissioning was completed in May 2023 just ahead of the official opening. It was a pleasure to work with ALEC, ASU and Holovis.”